Factory Price For Rust Converter Undercoating - Silver Dacromet Coating Nano Alloy Coating High Corrosion Resistance JH-9088 – Junhe Detail:

Minimum Order Quantity: 100 Kilograms

Packaging Details: 20kg/ Metal Barrel

Delivery Time: Ten days after receipt of advance payment

Supply Ability: 2 Tons per Day

Color: Silver

Density: 0.9-1.2g/ml

Diluent: Use Diluent Djust To The Coating Viscosity JH-9088B Diluent

Viscosity: 25-45s

Description

1 Product Information

According to the galvanized coating have poor corrosion resistance and defect of acid and alkali

resistant,our companyI developed JH-9088 high corrosion nano alloy coatings.It can improve the

corrosion performance of the coating,make the salt spray time increased to more than 1000 hours,

but also increase the hardness, acid and alkali-resistant on the coating surface, and the surface color

can be diversified.

2 Composition/ information on ingredients

The basic materials of this product is nano-alloy powder, toughening agents, film formers, organic

solvents and color paste, adding other additives mixed.

3 Performance Characteristics

This product can be use by dipping and spraying ways to treat on galvanized parts, parts surface treated uniformly, no blind spots. The treated parts,anti-corrosion ablity is ten times exceed galvanized workpieces, salt spray time increased to more than 1000 hours. And have excellent heat-resistant and antiacid, anti-alkali,anti-salt and other properties, its smooth surface, high hardness, anti-scratch, color can meet the needs of the deployment.

4 Market Application

This product is suitable for long-term corrosion protection for outdoor galvanized parts. Such as railway fasteners, bridges, buildings, power communications fasteners, etc.

5 Packing, Storage, Transportation

Packing:Steel drum,Net weight:20kg/drum(can also according to customer’s requirement).

Storage:Tightly closed,below 40℃,keep in indoor places, without direct sunlight.

Transportation:Should prevent rain, sun exposure, and shall comply with the relevant provisions of the transport sector.

Coating Process

Process flow

Galvanized parts dipping Spraying Pre-curing,Curing Inspection & Packing

Process parameters

Dipping: Room temperature,density:30-45s.

Centrifuge dripping: 210-270/min,30-60s

Spraying: Room temperature,density:25-35s.

Curing Condition

Pre-curing:Temperature:80-150℃,10-15min,choose whether pre-curing depend on the thickness of the workpiece.

Curing:Temperature:200-220℃,20-30min, box-type furnace or channel devices both ok.

Attentions

This product can use spraying and dipping ways for coating;

Fully stirring before use, should use special diluent to adjust viscosity;

Add centrifugal procedure for dipping process;

Cleaning appliance, use alcohol or ether organic solvents.

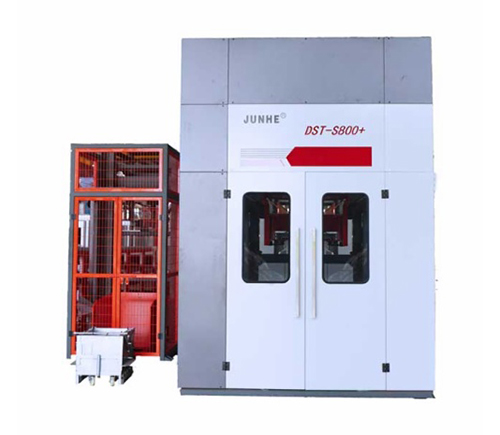

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Factory Price For Rust Converter Undercoating - Silver Dacromet Coating Nano Alloy Coating High Corrosion Resistance JH-9088 – Junhe , The product will supply to all over the world, such as: St. Petersburg, Curacao, Riyadh, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.