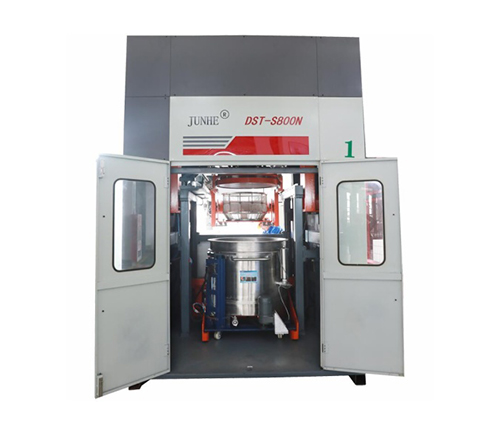

Factory wholesale Epoxy Corrosion Resistance - Junhe automobile brake disc induction heating spray line – Junhe Detail:

Minimum Order Quantity:1 set

Packaging Details:

Delivery Time:

Supply Ability:

Shortest production rate: 7.5 s

Max workpiece weight: 15 kg

Max temperature control accuracy: ±10 ℃

Max spray accuracy(thickness): ±2 µm

Equipment size: 10*20*5.8 M

Description

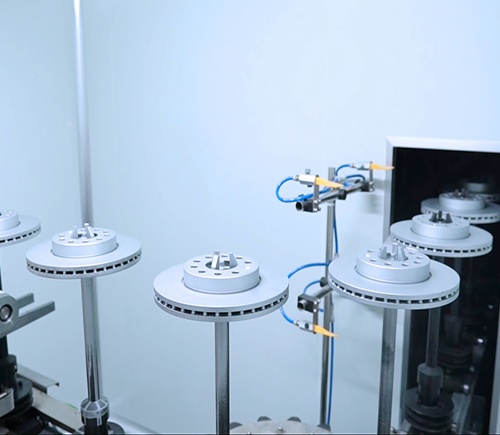

Suitable for brake disc special water, oil-base Zn-Al corrosion protection coating and metal zinc-rich paint.

Equipment main body:

Automatic feeding and unloading system, spraying and conveying system, automatic identification system, air blow system, dry type spraying booth, spray painting robot, paint supply system, curing heating system, preheating system, temperature detection after induction heating, air cleaning system, force cooling chamber, fixture cleaning equipment, complete machine cleaning isolation room, electric control system.

Features:

1. Automatically identify its model, intelligent adjustment of transmission, spraying and heating system.

2. Uniformly spraying and meet the coating standard of TL 193A, TL214, TL260, GB/T 26110-2010.

3. Induction heating, high conversion rate, low carbon environmental protection and energy saving 15%.

4. Servo platform control, precisely control of heating process which make the surface temperature of the disc uniform.

5. Integrated design of equipment and compact structure, save floor space 40%-60%.

6. Equipped with RFID system to collect and store data

7. Use the advanced integrated control systems and intelligent operating system, equipped with communication and transportation interface, which allow seamless connection of supporting equipment and unmanned workshop.

Technical Data

| Shortest production rate | 7.5 | S |

| Max workpiece weight | 15 | kg |

| Max temperature control accuracy | ±10 | ℃ |

| Max spray accuracy(thickness) | ±2 | µm |

| Cooling performance(comparison with room temperature) | ≤10 | ℃ |

| Equipment size | 10*20*5.8 | M |

Product detail pictures:

Related Product Guide:

Our organization has been focusing on brand strategy. Customers' gratification is our greatest advertising. We also source OEM provider for Factory wholesale Epoxy Corrosion Resistance - Junhe automobile brake disc induction heating spray line – Junhe , The product will supply to all over the world, such as: New York, Swaziland, Afghanistan, We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and perfect service . We also warmly welcome customers to visit our company and purchase our products.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.