Good Quality Rust Prevention Coatings - Zincover® 9730 Water-base Chrome-free Zinc Flake Coating – Junhe Detail:

Product Profile

Zincover®9730 is water-base chrome-free zinc flake coating paint,independently developed by Junhe.It does not contain heavy metal ions,meets RoHS standard,meets the requirements of China EnvironmentalProtection Law,no heavy metal emission,suitable for various fasteners and hardwares.Excellent anti-corrosion coating property. The paint has excellent salt spray resistance and strong adhesion ability,which meets thecoating standard requirements of fasteners and hardware parts of most auto companies.

FunctionalProprty

1、 Safety and environmental friendly: water-based,low VOC,no heavy metal,in line with GB24409 – 2020 GB30981 – 2020 GB / T18178 – 2020 GB30981 – 2020,also meeting the instruction requirement of EU RoHS ( 2002 / 95 / EC ) and ELV ( 2000 / 53 / EC ).

2、Excellent anti-corrosion property:

|

Thickness of coating layer |

Coating amount |

Salt-spray Test(ISO9227/ASTM B117) |

|

12~15μm |

≥240 mg/ dm2 |

1000h no red rust |

|

13~18μm |

≥240mg/ dm2 base coat+ Zincover® 9130 top coat |

≥1600h no red rust(top coat 1~3μm) |

3、Wide coating Proces range: dip spin coating,spray coating and Leaching.

4、Wide functional properties: coating layer resists 400 °C high temperature,no hydrogen embrittlement,strong recoatability.

5、Long storage time: after mixing part A and part B,stirring at 20-25 °C,the performance loss is less than 20% within 20 days.

Technical Parameter

|

Density |

1.3~1.4g/ml |

Ø800 centrifugal speed |

230~300 rpm/min |

|

Solid content |

38~40% |

Use viscosity(Zahn Cup #2) |

Dip spin: 60~80s,spraying: 30~60s,leaching: 20~40s |

|

Finess |

<20μm |

Pre-heating/Time |

20±10℃/more than10min |

|

Viscosity(Zahn Cup #2) |

20~30(A+B) |

Curing /Time |

320±10℃/more than 20min |

*These properties may vary depending on the substrate,process,batch and workpiece shape.

Application Field

Anti-corrosion coating of fasteners and hardware Components in automobile,wind power,photovoltaic andhigh speed railway industry.

Changzhou Junhe Technology Stock Co.,Ltd

Website:www.junhetec.com Email: marketing@junhe-china.com

Tel:86-519-85922787 Mobile: 13915018025

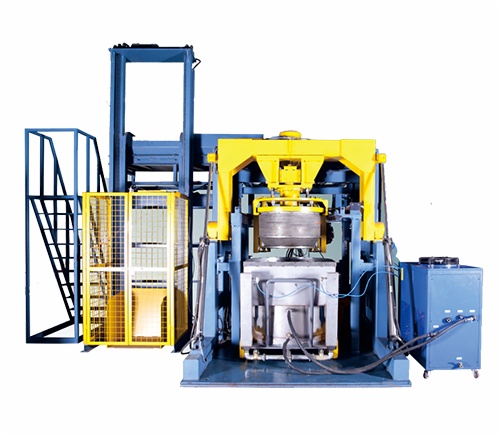

Product detail pictures:

Related Product Guide:

We persistently execute our spirit of ''Innovation bringing growth, Highly-quality making sure subsistence, Administration marketing reward, Credit history attracting clients for Good Quality Rust Prevention Coatings - Zincover® 9730 Water-base Chrome-free Zinc Flake Coating – Junhe , The product will supply to all over the world, such as: Namibia, Canada, Israel, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.