Introduction

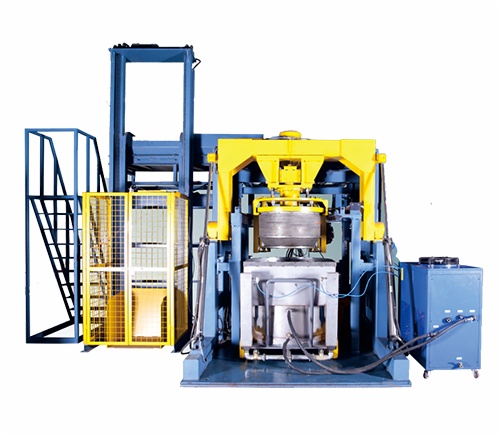

JUNHE® TDST0800H Automatic Gantry-Type Coating Machine can meet the coating requirement of blind hole automotive fasteners,hardware parts, batch control,high production rate,it can be centrifuged horizontally and vertically at nearly 90 degree,safety and environmental friendly,prevent mixing materials,double basket,low operating cost,informatization,intelligent and IOT upgrade.

Functional Proprty

1. Modular Standardization

Features modularization and standardization, with a built-in electrical cabinet.

The whole machine is assembled, ready for use upon hoisting, and easy to install.

Supports optional intelligent and IoT-enabled functions for convenient upgrades.

Matches Junhe® standard sintering furnaces with no debugging required.

2. Wide Range of Applicable Workpieces

Equipped with both automatic and manual feeding functions.

Automatic feeding for small workpieces and manual feeding for large workpieces.

Prevents collision and damage to workpieces.

3. High Good Product Rate & Efficiency

Adopts high-speed centrifugation and tilted low-speed flipping to ensure uniform surface coating.

Reduces the liquid accumulation rate of blind-hole parts.

Features dual-basket in-and-out design to improve efficiency.

4. Excellent Safety & Environmental Protection

Prevents paint splashing with a fully enclosed structure.

Equipped with a centralized waste gas collection system.

Suitable for the application of both water-based and oil-based coatings.

5. Good Batch Management

Each batch of workpieces is weighed and processed in accordance with process requirements.

The entire process runs automatically with full-process monitoring and recording.

No material jamming risk points throughout the process.

6. Multiple Optional Modules

Offers a variety of optional modules, including:Wearing parts are standardized and modularized. Modules support plug-and-play, enhancing flexibility and maintenance efficiency.

Coater module, feeding module, weighing module, anti-collision module

Unloading module, robotic handling module, coating temperature control module

Coating control and detection module, waste gas treatment module

Parameters

| Basket diameter |

Ø800mm |

Maxloading capacity |

180kg/basket |

| Shortest Production Cycle |

180s |

Max capacity |

3600kg/h |

| Vertical Centrifugal Speed |

320 r/min |

Exhaust gas collection rate |

95% |

|

Max tilting angle |

60° |

Suitable Workpiece Length |

≤ 200mm |

|

Machine size |

2550×2250×3280mm |

Total power |

≤30kw |

|

Suitable furnace |

Junhe LF Series Mesh Belt FurnaceJunhe LB Series Multi-Layer Furnace |

Suitable paint |

All types water-base and solvent-base paint |

|

Suitable work pieces |

≤200mm external and internal hexagon bolts,cross bolts,nuts,stamping parts |

||

*The above performance parameters may vary due to manufacturing process,electrical selection,installation size workpiece shape and process selection.