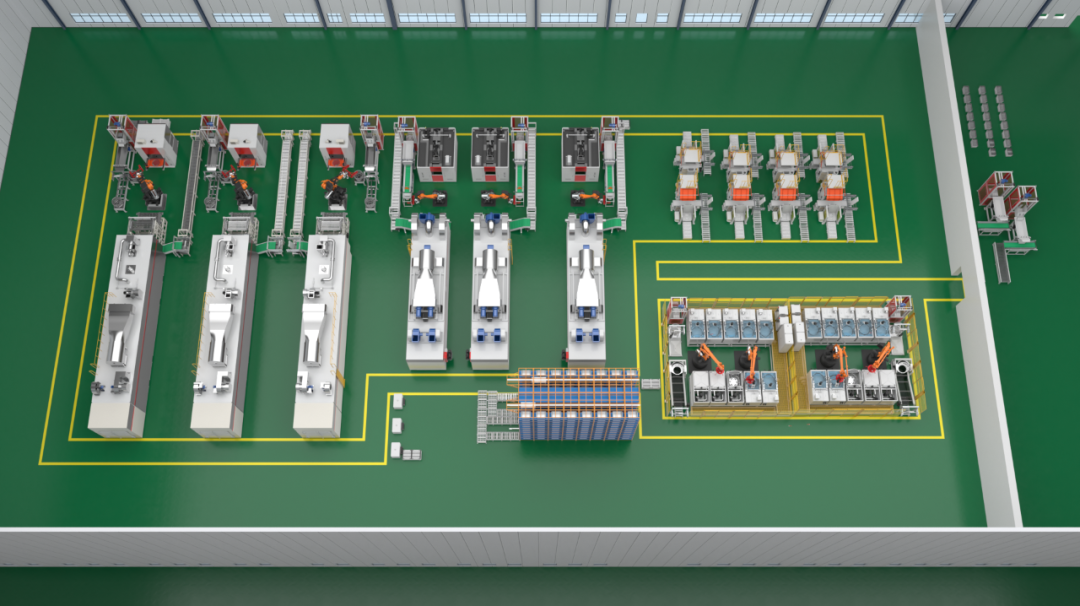

Junhe's pioneering Equipment and Digital-Intelligent Coating Production Line relies on a technical system featuring modular architecture and digital-intelligent interconnection. The production line enables flexible collaboration across the entire process, including cleaning, shot blasting, coating, curing, testing and packaging, with the following advantages:

Digital-Intelligent Interconnection · Intelligent Collaboration

Flexible Production · High-Efficiency Responsiveness

It supports switching between multi-variety, small-batch production and large-scale continuous production, rapidly responding to diverse order requirements and facilitating the flexible upgrading of manufacturing operations.

Green & Energy-Saving · Smart Manufacturing

The energy-efficient process chain, precise control and intelligent energy consumption management balance environmental protection and high efficiency, establishing a benchmark for sustainable smart manufacturing.

01 Cleaning Machine

JUNHE®QUDR0180 Multi-tank Automatic Cleaning Machine features high throughput, low energy consumption, supports multi-tank switching, and enables fully automated processes for efficient and flexible cleaning.

| JUNHE®QUDR0180 Multi-tank Automatic Cleaning Machine | |||

| Total Equipment Power | 260kw | Maximum Loading Capacity per Frame | 180kg |

| Cleaning Rotation Speed | 0.5r/s | Cleaning Temperature | 50±10℃ |

| Maximum Drying Rotation Speed | 280r/min | Floor Area | 9.5m*9.5m |

| Maximum Equipment Capacity | 20JPH(Frame) | Loading Method | Manual or AGV |

02 Shot Blasting Machine

Shot blasting machine features modular loading and unloading, and an integrated design that saves space. Equipped with pulse dust removal, it ensures a cleaner working environment and safe operation. After shot blasting, the workpiece achieves a surface free of rust, scale, over-blasting defects and loose dust.

03 Automatic Gantry-type Single-basket Machine

JUNHE®TDST0800R Automatic Gantry-type Coating Machine adopts low-speed material homogenization and high-speed centrifugation, delivering uniform coating without blind spots, minimal liquid accumulation, and high product yield. It features excellent safety and environmental performance, prevents material mixing, and ensures low operational costs.

| Automatic Gantry-type Coating Machine (JUNHE®TDST0800R) | |||

| Maximum Centrifugal Speed | 320r/min | Maximum Tilt Angle | 60° |

| Loading Capacity | 180kg/basket | Basket Dimensions | Ø800X450 |

| Shortest Takt Time | 180S | Single-Coating Capacity (Taking M8×50mm×2.0 Hexagon Head Bolts as an Example) | 3600kg/h |

| Module Installation Dimensions | 2550X2250X3280mm | Coating Liquid Loading Capacity | 360L |

| Suitable for stove |

Junhe mesh-belt furnace / multi-layer furnace |

Suitable coatings |

Various water-based and oil-based coatings |

|

Pooling rate control |

<5‰ | Total power | ≤30KW(Excluding robots) |

| Exhaust gas collection efficiency | 95% | Information system interface | 5G communication, equipped with IoT interface, cloud-based data platform, and compatible with AGV and MES systems. |

| Suitable workpieces for coating | External hex, internal hex, cross-head bolts, nuts, stamped parts, etc., with dimensions ≤200 mm | ||

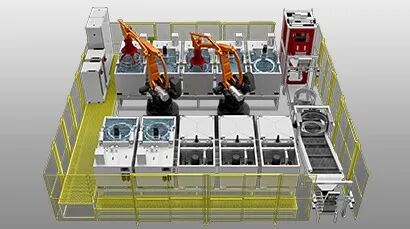

04 Planetary Coating Machine

The JUNHE® TDSP0500 Six-Basket Planetary Coating Machine is designed for automotive blind-hole fasteners and hardware components requiring zinc-aluminum micro-coating, batch traceability, and high yield. Featuring planetary centrifugation, it offers excellent safety and environmental performance, prevents material mixing, and ensures low operating costs.

|

Planetary Coating Machine JUNHE® TDSP0500 |

|||

| Loading Capacity | 60kgX3 | Basket Dimensions | Ø500×400mm |

| Coating Throughput (e.g., M8×50 mm×2.0 external hex bolts) | 3600kg/h | Minimum Cycle Time | 180s |

| Maximum Centrifugal Speed | 260r/min | Maximum Immersion Depth | 300 mm |

| Module Installation Dimensions | 3660x3000x3150mm | Total Power | 24 kW (excluding robots) |

| Suitable Ovens | Junhe mesh-belt furnace / multi-layer furnace | Applicable Coatings | Various water-based and oil-based coatings |

| Exhaust Gas Collection Efficiency | 95% | Pooling Rate Contro | <5‰ |

| Coating Tank Capacity | 700L | Information System Interface | 5G communication, IoT interface, cloud data platform; compatible with AGV and MES systems |

| Suitable Workpieces | Fasteners/clamps/hardware parts with size M6 ≤ ≤ M14, length ≤ 120 mm | ||

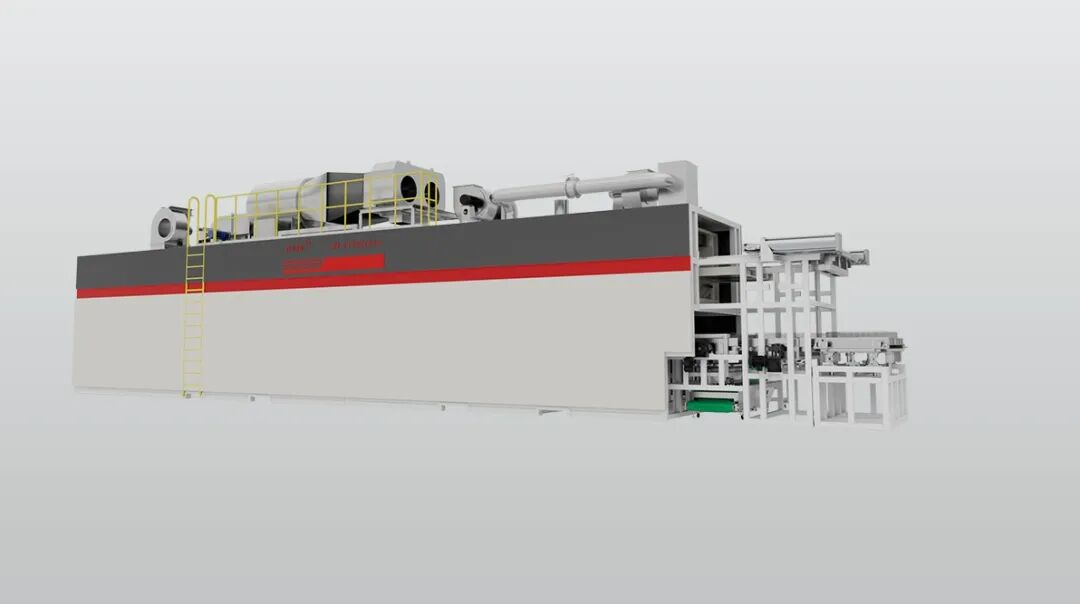

05 Stepping Batch-Type Three-Layer Furnace

|

Three-Layer Furnace JUNHE® LBGE3115

|

|||

|---|---|---|---|

|

Loading Capacity |

180 kg per tray

|

Workpiece Tray Dimensions

|

800 × 1500 mm

|

|

Furnace Temperature

|

Adjustable from 80°C to 360°C

|

Heating Method

|

Burner or electric heating (optional)

|

|

Energy Consumption

|

Burner: 21–23 m³/h<br>Electric heating: 110 kW/h

|

Total Tray Capacity/Production for Full Line

|

31 trays, maximum single-coating capacity 3,600 kg/h

|

|

Total Power

|

130 kW

|

Drive Method

|

3 min per tray, step-adjustable

|

|

Temperature Uniformity in Effective Zone

|

Cross-sectional ±10°C

|

Pre-drying/Sintering Time

|

12 min, 28 min

|

|

Module Installation Dimensions

|

12,500 × 2,750 × 4,365 mm

|

Suitable Workpieces

|

Height ≤150 mm

|

|

Suitable Coating Machines

|

Single-basket coating machine / six-basket planetary machine

|

Applicable Coatings

|

Various water-based and oil-based coatings

|

|

Exhaust Gas Collection Efficiency

|

95%

|

Information System Interface

|

5G communication, IoT interface, cloud data platform; compatible with AGV and MES systems

|

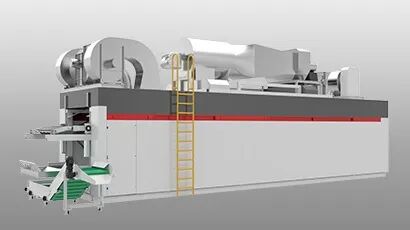

06 Stepping Batch-Type Two-Layer Furnace

The Junhe® LBGE3415 Stepping Batch-Type Two-Layer Furnace is designed to address sintering challenges for irregularly shaped parts and large components after coating or spraying. It features a stepping conveying system, prevents material mixing, enables batch traceability, and offers advantages in energy savings, space efficiency, and reduced labor requirements.

|

Two-Layer Furnace JUNHE® LBGE3415

|

|||

|---|---|---|---|

|

Loading Capacity

|

180 kg per tray

|

Tray Dimensions

|

800 × 1500 mm

|

|

Furnace Temperature

|

Adjustable from 80°C to 360°C

|

Heating Method

|

Burner or electric heating (optional)

|

|

Energy Consumption

|

Burner: 16–21 m³/h<br>Electric heating: 80 kW/h

|

Total Number of Trays / Production Capacity

|

34 trays, maximum single-coating capacity 3,600 kg/h

|

|

Total Power

|

130 kW

|

Drive Method

|

3 min per tray, step-adjustable

|

|

Temperature Uniformity in Effective Zone

|

Cross-sectional ±8°C

|

Pre-drying / Sintering Time

|

12 min, 30 min

|

|

Module Installation Dimensions

|

17,710 × 2,850 × 4,925 mm

|

Suitable Workpieces

|

Height ≤ 500 mm; suitable for coating of irregularly shaped parts and sintering of large components after spraying

|

|

Compatible Coating Machines

|

Single-basket coater / Six-basket planetary coater

|

Applicable Coatings

|

Various water-based and oil-based coatings

|

|

Exhaust Gas Collection Efficiency

|

95%

|

Information System Interface

|

5G communication, IoT interface, cloud data platform; compatible with AGV and MES systems

|

Post time: Dec-08-2025