Insulation, Flame Retardancy & Protection

/ Coating Protection /

With the adoption of new-generation power battery structures (CTP, CTB, CTC) and 800V fast-charging technology, the GB 38031-2025 standard sets higher safety requirements for power batteries, explicitly stipulating that batteries must not catch fire or explode under thermal propagation conditions. At the same time, the GB/T 36276 and CSA/ANSI C80-2025 standards also specify safety performance requirements for energy storage batteries under extreme conditions such as large-scale fire exposure, freezing rain and snow, floods, and high temperatures.

Driven by the global carbon neutrality trend, distributed grids are rapidly evolving from “supplementary energy” to “primary energy.” New energy utilization models such as V2G (vehicle-to-grid bidirectional energy interaction) and wind-solar integration are developing quickly, making the design, manufacturing, and application of power and energy storage batteries, electrical equipment, and power systems increasingly interconnected.

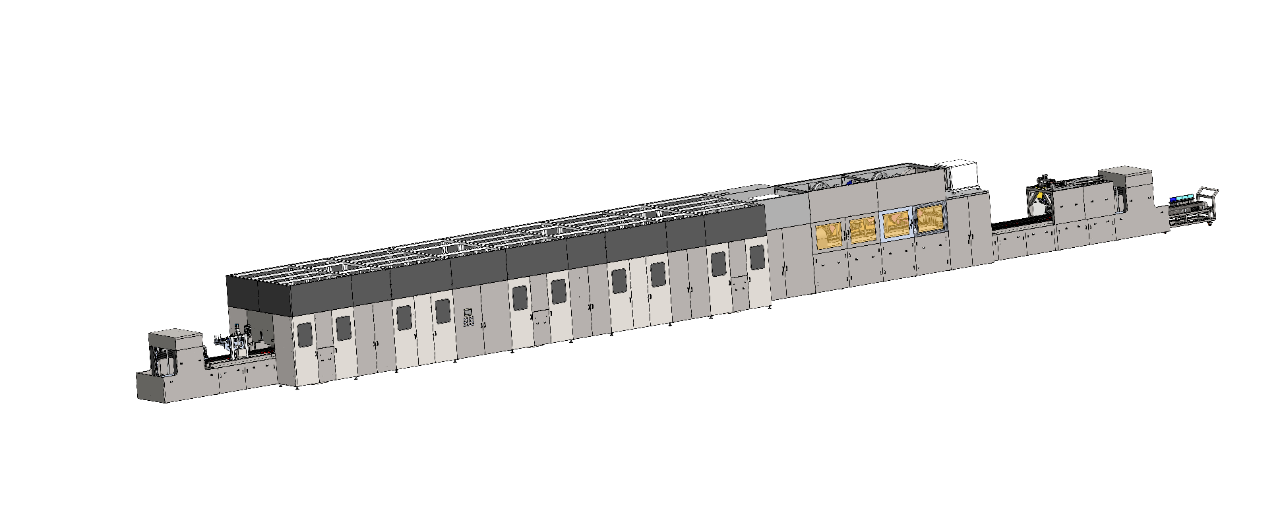

Against this backdrop, the demand for insulation, flame retardancy, fire resistance, and corrosion protection in batteries and electrical equipment is becoming more prominent. Traditional PET blue film solutions are now facing challenges and potential replacement by new processes such as powder coating, UV spraying, UV inkjet printing, and insulating electrophoresis. Meanwhile, the application of liquid insulation coatings—such as liquid cooling plate coatings and busbar insulating UV coatings—is opening up new directions for process upgrades in battery PACKs and electrical equipment.

How to ensure high-quality and high-performance coating protection under the requirements of energy conservation and emission reduction has become a shared challenge for OEMs, new energy battery enterprises, PACK factories (covering liquid cooling plates, upper and lower covers, trays, busbars, etc.), power and electrical companies, coating plants, as well as materials and equipment suppliers.

As a solution provider of UV coating systems for lithium batteries, our company has long been dedicated to the R&D of coating processes and equipment, with strong capabilities in designing and manufacturing related production lines. We are able to meet the cutting-edge requirements of power and energy storage batteries in insulation, flame retardancy, and environmental adaptability.

We also look forward to leveraging the upcoming EIC New Energy Battery “Insulation & Flame Retardancy, Fire & Corrosion Protection” Technology Conference as an opportunity to collaborate with partners across the industry chain, jointly exploring the future direction of coating protection for new energy batteries and electrical equipment.

Post time: Sep-10-2025