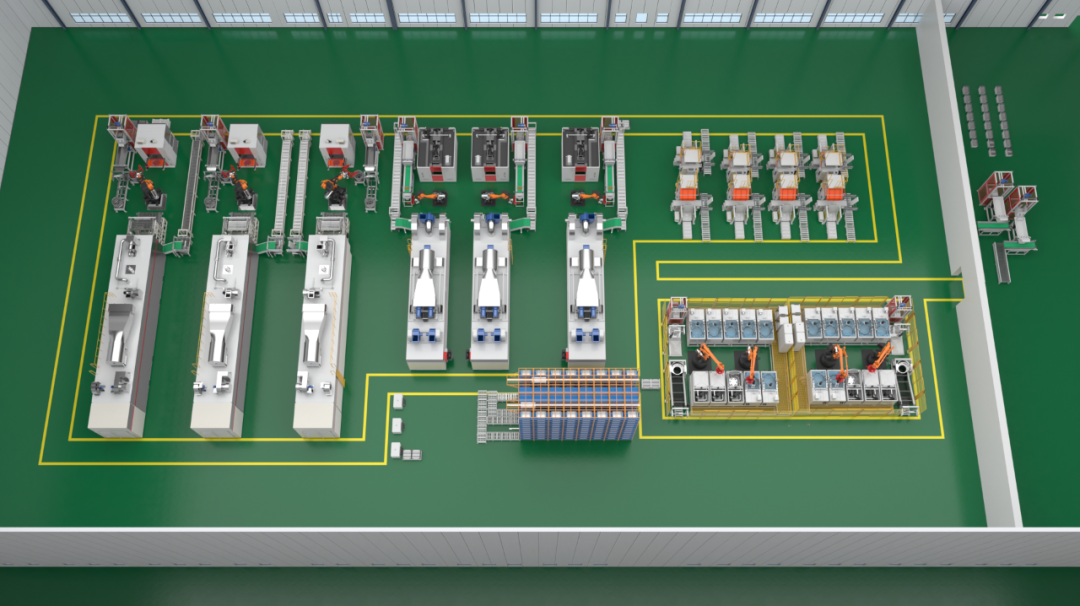

Digital & Intelligent Zinc-Aluminum Coating Integrated Line

01 Digital & Intelligent Coating Integrated Line

The accelerating trends of automotive lightweighting and electrification are driving an increase in the number of fasteners used and a rise in their reliability requirements. Coupled with higher demands from OEMs for traceability and consistency in the coating process, traditional coating processing models are no longer sufficient for future quality management systems. How to achieve more flexible production scheduling, full process traceability, and zero batch mixing—all while guaranteeing stable quality—has become a real-world challenge for a growing number of processing companies.

Addressing this industry-wide pain point, JUNHE has leveraged its extensive experience in coating processes and equipment to develop the Digital & Intelligent Coating Integrated Line. This line features a fundamental reconstruction, from its underlying architecture to its system logic, establishing three core capabilities: flexible design, traceable design, and anti-mixing design.

02 Three Core Capabilities

I. Flexible Design: No More “One-Stop Halts the Entire Line”

Traditional coating production lines often rely on mechanically rigid connections like incline conveyors and secondary returns, lacking buffers and decoupling between upstream and downstream processes. If any single process is paused for reasons such as a coating change, equipment maintenance, or parameter adjustment, the entire line is forced to stop. This leads to low equipment utilization, making it difficult to insert rush orders and slow to switch between batches.

The JUNHE Digital & Intelligent Coating Integrated Line structurally overcomes this limitation:

- AGVs replace rigid connections, eliminating forced serial linkage between processes.

- A line-side buffer warehouse is set up to enable batch consolidation and takt time adjustment.

- Individual units can operate and be maintained independently, preventing chain-reaction shutdowns.

Furthermore, the system is deeply integrated with the MES (Manufacturing Execution System), enabling dynamic production scheduling based on information such as order delivery dates, batch-specific processes, and equipment status. This results in more organized production plans, more stable production cycles, and higher equipment utilization.

In the workpiece handling stage, robotic material handling is introduced to reduce the risk of damage from drops—a common issue with traditional rigid connections that have significant fall heights. This effectively ensures the stable pass rate of the thread go/no-go gauge.

II. Traceable Design: Ensuring Every Batch is Documented and Verifiable

In high-quality coating processing, “doing it right” is crucial, but “being able to trace it” is equally critical.

The JUNHE Digital & Intelligent Coating Integrated Line uses the MES as its core to build a clear and complete traceability logic:

- Incoming materials undergo manual inspection, weighing, and sorting, then are placed in baskets and scanned to create a digital record.

- The scanned information enters the MES, which automatically matches the corresponding process sheet and generates a production schedule.

- When workpieces arrive at key stations like shot blasting, coating, and curing, scanning the code instantly retrieves the process parameters.

- The Industrial PC (IPC) interacts with the MES:

- Process parameters and task instructions are automatically dispatched.

- Actual processing data and equipment status are uploaded in real-time.

Ultimately, every batch forms a complete data chain:

Incoming Material → Process → Equipment → Parameters → Status → Results.

This truly achieves a state where “the process is checkable, the results are traceable, and responsibility is assignable.”

III. Anti-Mixing Design: Keeping “Mixing Risks” Out of the System

Material mixing is one of the most unacceptable yet common problems in fastener coating processing.

JUNHE treats anti-mixing as a vital component of its digital intelligence quality control, constructing a full-process anti-mixing system through a multi-layered mechanism of physical isolation + system verification + data tracking.

① Physical Isolation for Inherent Error-Proofing

- Trays in three-layer/double-layer furnaces move in a step-by-step manner, ensuring physical separation throughout the process.

- Independent processing baskets/tooling are used, with one basket per batch.

- The line-side buffer warehouse is partitioned for storage, ensuring different batches are not mixed or mistakenly retrieved.

② System Verification: Immediate Halt on Error

- Scanning and verification are mandatory at basketing and key stations.

- If the batch and process do not match, the equipment is prohibited from starting.

- AGV tasks are bound to specific batches, preventing cross-batch transportation.

- The robot performs batch identification before picking or placing, preventing misplacement.

③ Data Tracking for Full-Process Monitoring

- The MES displays the real-time location, quantity, and status of each batch.

- Automatic counting is performed upon exiting the furnace and the line, with results compared against the expected quantity.

- Immediate alarms are triggered for any quantity or process anomalies.

- Batch data from the entire line is automatically archived, supporting rapid traceability and review.

Through the superposition of these multiple mechanisms, the risk of material mixing caused by human intervention is minimized to the greatest extent, achieving a truly “zero-mixing” operational model.

The JUNHE Digital & Intelligent Coating Integrated Line is not a simple aggregation of equipment. Instead, it redefines the operational model of a coating line at the structural, systematic, and managerial logic levels, providing a more stable, reliable, and valuable long-term development path for zinc-aluminum coating processing of fasteners.

Post time: Dec-22-2025