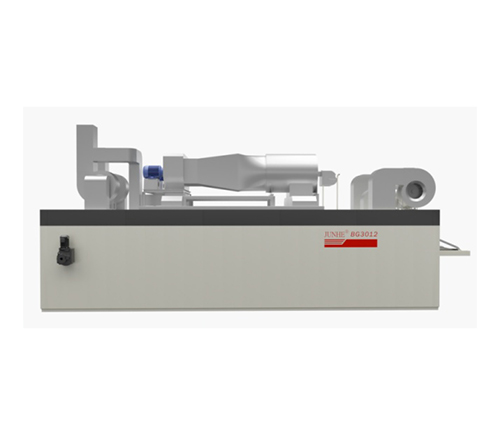

Online Exporter Zinc Flake Coating Machine - Black Dacromet Coating Paint Top Coat JH-9321 – Junhe Detail:

Payment & Shipping Terms:

Minimum Order Quantity: 100 Kilograms

Price: Negotiable

Packaging Details:30kg/ plastic barrel

Delivery Time: Ten days after receipt of advance payment

Supply Ability: 2 Tons per Day

Color: Black

PH: 8.0-9.0

Viscosity: ≥50s

Thickness Of Dry Film: 10-20 (micron)

Hardness: ≥1

Adhesion(degree): ≤1

Description

1) The main ingredient is water-base inorganic silica , mixed with corrosion protection assistant.

2) The product cost is low.

3) The coating layer is smooth, weak acid and alkali resistant.

Technical Data:

| No. | Item | Data |

| 1 | Appearance | Black , fine and smooth |

| 2 | Viscosity | ≥50s |

| 3 | PH | 8.0-9.0 |

| 4 | Thickness of dry film | 10-20 (micron) |

| 5 | Hardness | ≥1 |

| 6 | Adhesion(degree) | ≤1 |

| 7 | Bend | 1(mm) |

| 8 | heat and humidity resistance | 240 (h) |

Instructions and attention:

1. Dip coating, Spray coating etc;

2. It should be stirred fully befor usage; distilled water or deionized water can be used to adjust viscosity; Operating viscosity: 30-60s.

3. When the environment humidity higher than 85%,can add certain industrial alcohol to adjust viscosity;

4. Curing condition: 80℃/10min+140℃/30min;

5. Cleaning appliance: running water can be used;

6. Avoid acid substances, or polymerization and deterioration will happen;

7. This product can be used alone, the coated surface request oil free, dust free and dry, the better make pre-treatment of degreasing, derusting, and phosphating.

Processing method:

A 1 base-coat+ 1 Top coat

B 2 base-coat+ 1 Top coat (heavy corrosion protection)

Professional Electroplated Zinc Coating , Black Dacromet Plating Alkali Resistant

Process Parameter:

Dip Coating Temperature RT

Operateing Viscosity 45-60 S

Centrifuge 210~270 RPM/min 10s X 4-8 times

( Centrifuge device can not be mix used with spin dyrer )

Spray Coating Temperature RT

Operateing Viscosity 30~40 S

Curing: 80℃ 10min + 140℃ 20—30min

Corrosion protection of b process flow

Corrosion resistance: ≥1500h (NSS)

Sea water resistance: 25℃≥1500h

Technical Data

| No. | Item | Data |

| 1 | Appearance | Black , fine and smooth |

| 2 | Viscosity | ≥50s |

| 3 | PH | 8.0-9.0 |

| 4 | Thickness of dry film | 10-20 (micron) |

| 5 | Hardness | ≥1 |

| 6 | Adhesion(degree) | ≤1 |

| 7 | Bend | 1(mm) |

| 8 | heat and humidity resistance | 240 (h) |

Product detail pictures:

Related Product Guide:

We keep on with our business spirit of "Quality, Performance, Innovation and Integrity". We goal to create much more worth for our customers with our rich resources, state-of-the-art machinery, experienced workers and exceptional providers for Online Exporter Zinc Flake Coating Machine - Black Dacromet Coating Paint Top Coat JH-9321 – Junhe , The product will supply to all over the world, such as: Mauritius, Nepal, Luxemburg, We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and perfect service . We also warmly welcome customers to visit our company and purchase our products.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.