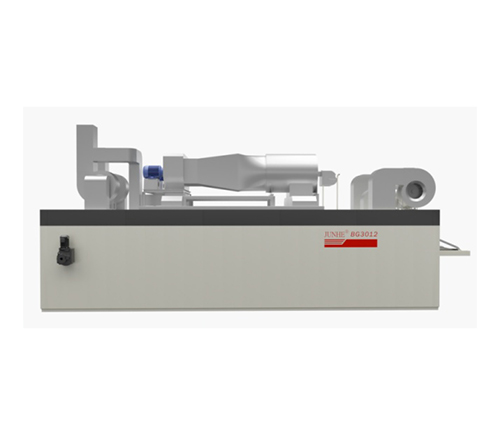

Top Suppliers Cathodic Dip Painting - BG3012 Stepping Tray-Type Curing Furnace – Junhe Detail:

Product Profile

JUNHE®stepping tray-type curing furnace can meet the coating requirement of automotive fasteners and hardware parts, batch control,low energy consumption,safety and environmental friendly,prevent mixing materials,low operation cost, informatization,intelligent and IOT upgrade.

FunctionalProprty

1、Module standardization: stable performance, modular, standardized design, whole machine assembly,plug and play, easy installation, intelligent selection, easy upgrade, matching with Junhe standard coating machine.

2、Smallland occupation: compact equipment, multilayer integrated stereoscopic structure, nearly two-thirds less area than conventional curing furnace.

3、Excellent energy saving and environmental friendly: cooling energy recovery, integral enclosed design, centralized collection of exhaust air.

4、Good batch management : stepping tray type continuous pre-heating and curing,each tray matched with each basket of coating machine,batch data control, prevent mixing parts,good batch management.

5、Low operation cost: pre-heating, curing and cooling energy complementary control, energy saving, saving more than 20 % than conventional curing furnace, one side loading and unloading, reducing intelligent investment and labor cost.

Technical Parameter

| Max loading capacity: | 200kg/tray | Tray size: | 1200×1150mm |

| Furnace temperature | 80~360℃,adjustable | Heating method | Gas heating,electrical heating,optional |

| Natural gas energy consumption | <25m³/h | Total trays/capacity | 30 trays,one coat max capacity: 6000kg/h |

| Total power | ≤35kw | Transmission type | 2-4min/tray,stepping and adjustable |

| Effective area furnace temperature uniformity | Cross section: ±5℃ | Pre-heating/Curing time | 12~24min、22~44min |

| Machine size | 12500×2750×4365mm | Suitable workpieces | Auto parts require batch control |

| Suitable coating machine | JUNHE®DSP T500、JUNHE®DST-D800 series | Suitable paint | Suitable for all types water-base and solvent-base paint |

*The above performance parameters may vary due to manufacturing process,electrical selection,installation

size workpiece shape and process selection.

Product detail pictures:

Related Product Guide:

To create far more benefit for customers is our company philosophy; customer growing is our working chase for Top Suppliers Cathodic Dip Painting - BG3012 Stepping Tray-Type Curing Furnace – Junhe , The product will supply to all over the world, such as: Auckland, Pretoria, Romania, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.