Minimum Order Quantity: 1 Set

Packaging Details: 20 OT

Delivery Time: Three months after receipt of advance payment

Supply Ability:1 Set per Month

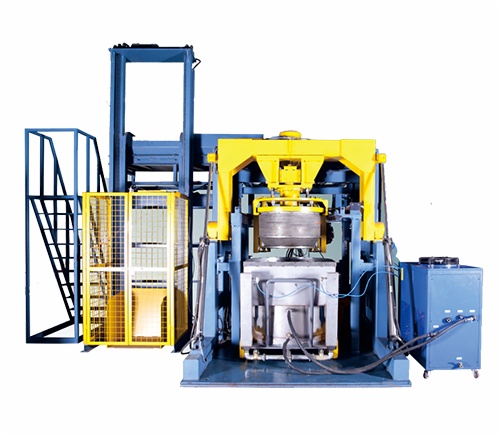

Color: Bule & Yellow

Max Load Of Basket: 180kg

Max Spinning Speed:320r/min

Shortest Production Rate: 180s

Max Capacity: 3600kg/h(For example, based on M10×50mm full thread)

Suitable Workpiece Weight: ≤600g

Suitable Workpiece Length: ≤18cm

Description

Junhe Coater is compatible with various materials including zinc-aluminum micro-coatings, topcoats, sealants, and Teflon, meeting the needs for coating automotive blind-hole fasteners and hardware parts, as well as batch control with high yield rates.

It adopts low-speed material homogenization and high-speed centrifugation, ensuring uniform coating without dead corners, minimal liquid accumulation, and high yield. Meanwhile, it features advantages such as safety and environmental protection, prevention of material mixing, dual-basket configuration, and low cost, and supports informatization and IoT upgrades.

Equipment main body

Isolating room, coating machine, weighing loading system, distributing system, control system.

Features

1. Modular Standardization

Features modularization and standardization, with a built-in electrical cabinet.

The whole machine is assembled, ready for use upon hoisting, and easy to install.

Supports optional intelligent and IoT functions for convenient upgrades.

Matches Junhe® standard sintering furnaces with no debugging required.

2. High Good Product Rate & Efficiency

Adopts low-speed material homogenization, high-speed centrifugation, and tilted low-speed flipping.

Ensures uniform surface coating and reduces the liquid accumulation rate of blind-hole parts.

3. Excellent Safety & Environmental Protection

Prevents paint splashing with a fully enclosed structure.

Equipped with a centralized waste gas collection system.

Suitable for both water-based and oil-based coatings.

4. Good Batch Management

Each batch of workpieces is weighed and processed in accordance with process requirements.

The entire process runs automatically, with full-process monitoring and recording available.

No material jamming risk points exist throughout the process.

5. Multiple Optional Modules

Offers a variety of optional modules, including:Coater module, feeding module, weighing module, anti-collision module

Unloading module, robotic handling module, coating temperature control module

Coating control and detection module, waste gas treatment module

Wearing parts are standardized and modularized. Modules support plug-and-play, enhancing flexibility and maintenance efficiency.

Technical Data

| Centrifugal speed | 0~320 | r/min |

| Max tilting angle | 60 | ° |

| Max load of basket | 180 | kg |

| Shortest production rate | 180 | s |

| Max capacity | 3600 | kg/h |

| Suitable workpiece weight | ≤600 | g |

| Suitable workpiece length | ≤18 | cm |