An increasing amount of chemicals such as phosphorus-containing degreasing agents and phosphate solution are consumed in industrial production in China, resulting in phosphorus pollution. Given traditional phosphate coatings increase energy consumption and pollution, new environmentally friendly pre-treatment agent began to emerge in the 1990s including several mainstream technologies such as Henkel zirconium salt conversion film and ECO silane technology. Environmentally friendly coating agent has a wide range of industrial applications across the world.

JH-8006 Environmentally friendly coating agent

Changzhou Junhe Technology Stock Co., Ltd. produces JH-8006, a new type of environmental protection product with low energy consumption and high performance, by making use of silane, zirconium salt and silane zirconium salt compound. Adding special film-forming additives allows the product to be chemically treated on the surface of steel, zinc plate and aluminum and generate heterogeneous insoluble nano-level environmental-friendly conversion film. This conversion film has excellent corrosion resistance and impact resistance, thus improving the coating adhesion. JH-8006 environmentally friendly coating agent (titanium agent) contains no phosphorus, zinc, calcium, nickel, manganese, and chromium, so its waste water can be discharged after simple neutralization treatment.

Advantages of environmentally friendly coating agent (titanium agent)

1. The thickness of environmental-friendly coating agents is basically 30-80nm.

2. It mainly include ceramic coating, silane coating, and titanium composite coating, etc.

3. The vitrified agent is based on zirconium salt, the silane agent is based on organosilane, and the titanium agent is based on titanium salt with stable performance combined with the advantages of vitrified and silane.

4. Zirconium salt in vitrified agent is extremely insoluble in water and extremely insoluble in acid; silane is an organic substance with poor alkane stability and easy hydrolysis. On the basis of vitrified film, the titanium agent is upgraded through adsorption of silane chemistry and titanium salt, to increase adhesion and salt spray performance.

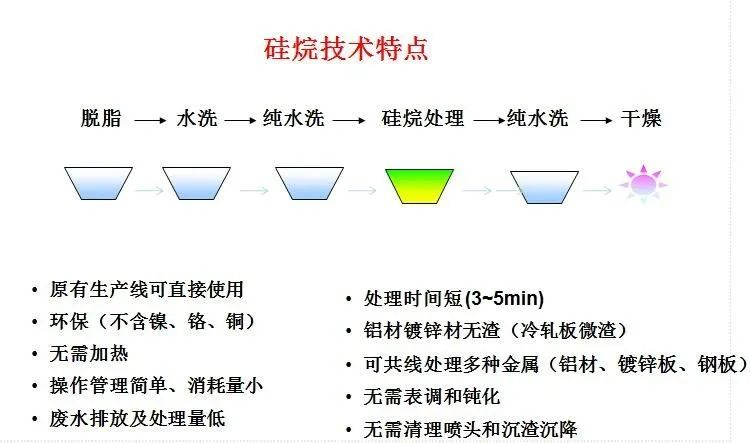

Process differences between environmentally friendly coating agent and phosphate coating

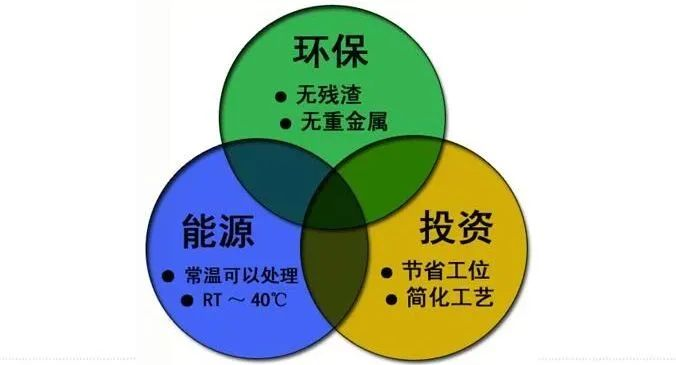

1. Environmentally friendly coating agent can be kept at room temperature.

2. Surface activation process is deleted in the production of environmentally friendly coating agent.

3. Minimized slag content ensure little damage to equipment and increased service life of equipment.

4. Washing water used in the production of environmentally friendly coating agent can be recycled, thus cutting energy consumption by about 30%.

5. Only the pH value should be tested during operation. Silane/vitrified coating: 4.5-5; composite titanium coating: 2.5-3.5.

6. Pickling process is not suitable for vitrified or silane coating, while pickling process is adopted for the production of titanium coating.

Effect differences between environmentally friendly coating agent and phosphate coating

1. There is a layer of dust on the surface of phosphate coating, while there is no dust after applying environmentally friendly coating agent.

2. Environmentally friendly coating agent contains no phosphorus, heavy metals and nitrite.

3. The color of phosphate coating is greyish white and gray, and the color of environmentally friendly coating agent is natural, light yellow and light blue. The color difference is mainly determined by the concentration.

Cost effective features of environmentally friendly coating agent

1. It’s a healthy material and causes no harm to the operator.

2. It can be stored according to general chemical standards.

3. No sedimentation, no tank emptying, very little chemical consumption and addition.

4. The supply quantity of washing water is reduced.

5. Environmentally friendly coating agent contains no volatile organic substances, and its consumption is about one-sixth of phosphate coating, which reduces environmental protection costs.

6. Low PH value, low corrosiveness to equipment and direct discharge.

7. The minimum reaction time of phosphate coating to the workpiece is 7 minutes, while the minimum reaction time of environmentally friendly coating agent to the workpiece is only 2 minutes.

Precautions in the actual use of environmentally friendly coating agent

1. The water quality should not be too hard and it is best to use pure water, to ensure good quality performance and prolong the service life of the tank solution.

2. No cast iron tank should be used, otherwise the tank will be eroded and active ingredients will be lost. Junhe Technology recommends you use materials except cast iron, such as grade 304 stainless steel, or cast iron tank with glass fiber reinforced plastic lining or hard PVC and PE lining.

3. Phosphate slag should be cleaned during the rebuilding of phosphate coating production line.

Post time: May-13-2022